Learn – How CBD Gummies Are Manufactured So You Buy The Best Wholesale Delta 8 Gummies for your shop.

There are several ways to make cannabidiol or CBD gummies. They are portable and easy to take as a snack since no dropper or measuring device is needed. They also taste better than some other CBD products, such as tinctures. However, it is essential to note that not all CBD gummies are the same.

To ensure you’re buying a quality CBD product, research to discover the best wholesale Delta 8 gummies for your money. You’ll see your sales go through the roof when you sell high-quality Delta 8 Gummies and CBD products.

How Are CBD Gummies Manufactured and Tested

First, the manufacture starts with organically grown hemp plants to make CBD oil. The Delta 8 gummies are made using modern food manufacturing equipment. The recipe with CBD oil is mixed to exact specs and then added to large cauldrons, where it is heated to the correct temperature. From there, it goes to the injection machine, which injects the right mixture into the molds.

The gummies are then chilled as they run along the conveyor. They come out, in the end, ready for packaging.

A Quality manufacturer will Lab-test your CBD gummies to contain less than 0.3 percent tetrahydrocannabinol (THC), which should be made from hemp grown in the United States.

The gummies are also tested for purity and safety. An ISO compliant lab will test the gummies and provide a certificate of analysis (COA) confirming that they contain no more than 0.3 percent THC and are free of pesticides, heavy metals, and molds. This is an essential step when asking how CBD gummies are manufactured.

It would help if you also considered the company’s manufacturing processes, product potency, overall ingredients, customer reviews, whether the company has received an FDA warning letter, and whether it makes any unsupported health claims.

The Making of Wholesale CBD Gummies

Creating CBD-infused gummies begins with isolating the CBD. CBD is a natural chemical compound produced by the hemp plant that does not cause a high. Most CBD products are derived from hemp, a type of cannabis plant. Cannabis and hemp have different chemical constituents.

To get CBD oil, it is necessary to separate oily hemp resin from the plant material. CBD is locked away inside cannabis resin. The safest way to do that is to use the same process used in the food industry.

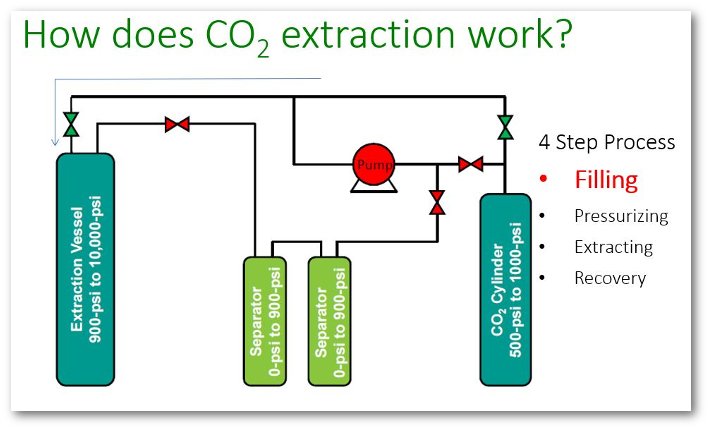

How Are Wholesale Delta 8 Gummies Manufactured – The Supercritical Co2 Extraction Method

Due to the use of highly flammable products such as butane, ethanol, isopropyl, propane, or alcohol, solvent extraction is more dangerous. By dissolving the terpene and cannabinoid contents of hemp flowers, these solvents are used to separate CBD from the plant matter and allow it to be concentrated.

When CO2 is exposed to high temperatures and pressure, it becomes a solvent, reaching a “supercritical” state when exposed to high pressure. Due to its lack of chemical residue in solvents like butane, supercritical CO2 extraction creates a purer CBD product. It is also non-flammable, which means fewer fire risks are involved in the extraction process.

Even though supercritical CO2 extractions are more expensive, they produce a purer product. They are considered the gold standard in the cannabis industry. A trustworthy provider of CBD gummies will usually list the manufacturing process directly on their website for consumers’ benefit. The method of extraction a company uses can also be found on the company’s website.

Once the CBD has been extracted from resin or oil, it is refined further to isolate and remove impurities. It is then ready to infuse into gummies. Making gummy candies is similar to making extra-thick Jell-O. All Wholesale Delta 8 Gummies contain three essential ingredients: sugar, a thickener like gelatin or fruit pectin, and flavoring, regardless of whether they are infused or not.

The ingredients must be mixed, heated, and poured into molds when making wholesale CBD gummies. CBD starts to degrade when the temperature reaches 392°F or 200°C. It’s best to add the isolate at the end of the cooking process. To ensure the appropriate texture, natural dyes, preservatives, starches, and other ingredients may be added too. Once everything has been combined in a mold and has cooled down completely, we get our finished product which can then move onto packaging.

Wholesale Delta 8 Gummies often contain animal products such as gelatin made of animal collagen, so they are not vegan. If you do have dietary restrictions, make sure you read the ingredients before you make a purchase. Some vegan-friendly products use vegan fruit pectin instead of animal-derived gelatin.

Manufacturing VEGAN gummies are now quite popular even though gelatin is healthy and forms collagen. Specify PECTIN (Vegan) or BLEND (regular) when you place your order.

CBD Gummies Made Local In Your Shop

Some people try to make gummies at their shops. The first step to making CBD gummies locally is buying a CBD tincture from a reputable manufacturer and following the exact instructions. You can make gummies in any shape or flavor, allowing you to be creative and versatile. It takes the following ingredients to make CBD Gummies: one pack of gelatin, either regular or vegan, fruit juice, a bottle of CBD tincture, and sugar.

CBD gummies can be made by following any homemade gummy candy recipe and adding a few drops of CBD tincture after it has been cooked but before it has hardened.

While this method is novel, most shop owners order their gummies in bulk or have them privately labeled. They do not want to be bothered with the certifications and approvals.

Which Wholesale Delta 8 Gummies Is Right For Your Shop?

CBD products and Edibles like Delta 8 Gummies come in various sizes, strengths, and strains, as well as regular or vegan. You’ll want to carry an assortment.

You’ll also have to decide if you want to buy your gummies pre-packaged, in bulk for packaging locally at your shop, or private label. Here are the advantages and disadvantages of each:

1. Buy Pre Packaged Wholesale Gummies. These are commonly purchased because the product already has a following. Customers are familiar with them. They are easy to merchandise and sell. They come in a wide variety of strains, sizes, and strengths. The disadvantage is they generally cost more than the other types. Our Sweet 8 Brand Wholesale Delta 8 Gummies are highly popular; you make more when you buy directly from the manufacturer.

2. Buy Wholesale Delta 8 Gummies In Bulk. Buying in bulk has always been a way to save money, and buying bulk wholesale gummies is no different. The shipping is generally less, and you can package them as you want. The disadvantage is more labor to get them to your shelves.

3. Buy Private Label Delta 8 Gummies. Private label is the way to go if you want your brand without the hassle of doing the manufacturing. Private-label gummies are used for promotions and giveaways in trial sizes. Regular and large sizes are made to sell to your customers. You can get them in Vegan or regular. The only disadvantage here is more lead time and having the labels designed.

We hope this guide to How Are CBD Gummies Manufactured has been helpful.

For more information on purchasing wholesale CBD food products, Delta 8 products, and other head shop items for your shop, use the contact box below.

Sweet Southern Trade

Buy Wholesale Delta 8 Gummies Direct From The Manufacturer And Save

Ask about a wholesale account now

[erforms id=”38080″]